I love my job. I’ve been a technician for just on thirty years now, and still enjoy the feeling of solving a complex engine management issue.

I no longer operate in a “bricks and mortar” shop – rather I subcontract my services to those workshops in need of diagnostic help.

Today I had a call about an Amarok.

Now, call me sick, but I quite like Volkswagens. Not the old ones mind you, but the newer versions when VW, AUDI, Skoda, and Lamborghini got together. I still question the mental state of their engineers now and again – but console myself with the knowledge that there are technicians out there that like the Land Rover product.

The Amarok in question is a 2014 Bi-Turbo job with the 2.0 litre CSHA powerplant. My customer (the workshop owner) stated that the customer had the vehicle diagnosed elsewhere, but the shop in question was too busy to perform the repair.

The original diagnosis was for two DTC’s – P242A(00) and P246E(00). This was diagnosed as faulty exhaust temperature sensors and three new units were purchased. The customer presented these parts with the vehicle to the workshop I was subcontracting to.

My first step in any engine management diagnostic is to quickly check the battery’s condition and that of the charging system – if you work on any euro vehicle, then you understand why this is a critical first step.

The next item on the agenda is checking the live data from these sensors. I tend to use an ambient air temperature as a reference when I’m checking any temp sensors. With a cold exhaust system, the three sensors in question should be very similar to the ambient.

In this case – all three were registering 1000 degrees Celsius. Well there’s your problem……..!

We won’t condemn the sensors just yet…….

Next up is a search of the circuit diagrams and some information on how the circuit works. Since these exhaust sensors are of the PTC (positive temperature coefficient) type, when there is an open circuit, the sensor will read a max value. This is opposite to a coolant temp sensor which is a NTC (negative temperature coefficient) type. When the CTS is open you will see the data at its lowest value – around minus 40 degrees Celsius.

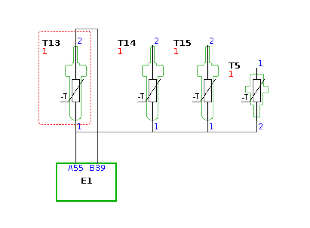

Each of the three exhaust sensors are monitored by individual pull up resistors within the ECM. But they share a common ground. So they are fairly easy to test.

With each sensor unplugged, I should see around five volts on the multimeter when connected across the harness side of the connector with the ignition on.

In this case, I had zero volts. A quick test of the ground circuit at each sensor also revealed zero volts. I then rechecked the monitored circuit voltage with my black meter lead attached to battery negative. The only sensor to register five volts during this test was the pre-turbo one.

Hmmm. It’s unusual to see all but one value missing. I then went to the ECM and checked the monitored voltage here. Terminals A32, A34, and B39 showed a value of 5.01 volts. This tells me the ECM and ECM connectors are OK.

I then connected my multimeter between battery positive and ECM terminal A55 to confirm the ground circuit was good. And sure as the sun rises over the Pacific Ocean, I had battery voltage displayed on the meter.

The diagnosis is an open circuit in the harness between the temperature sensors and the ECM.

I started my visual of the wiring harness at the ECM and followed it through the firewall towards the centre of the vehicle where it exits the cabin once again.

And this is the point where I showed my customer where the rodents (rats) had chewed their way through about four hours’ worth of harness repair.

I’m not sure who ordered and paid for the temperature sensors – but in this case, the parts are now surplus to vehicle needs. The original diagnostic was flawed. If only the technicians would adhere to the old saying “less haste – more speed”

Like I said earlier, I love my job because every day I see something new.