Autopilot. No, not the Tesla self-drive system, but the way we describe our actions when working, but not really thinking about it. This nearly tripped me up on a recent air conditioning job that went through the shop.

You know how it is, the jobs seem to blend together as you follow the same process day in and out.

a) Performance test, b) Diagnose fault, then c) repair.

Rinse and repeat……….. except when the vehicle is an Audi A5 with a non-operative AC system.

This vehicle failed the performance test. While the refrigerant pressures were spot on – about 500kpa on a 22-degree day, the AC compressor was not activating, meaning the low-pressure side was not pulling down and the high side was not increasing.

OK. Well, that narrows the fault to about a hundred possibilities. Once I had confirmed the compressor drive belt was still attached, the compressor was not seized and the magnetic clutch was not receiving a command, it was time to look at the HVAC control unit with the scan tool.

VAG vehicles have this cool function whereby faults for the HVAC are registered as data lines. You can access this data via “Group (08) – Actual Values”

0 = No shut of code (compressor should be running – all OK)

1 = Excessive system pressure (over charge or faulty pressure switch)

2 = Cooling fan fault (Check cooling fan and wiring)

3 = System pressure to low (Refrigerant leak, pressure switch fault)

4 = not used

5= no engine speed detected (Start Engine check live data for engine speed)

6 = Econ button pressed (switch off ECON button, AC Panel issues)

7 = AC Off (No blower speed detected)

8 = Outside Temp to low (Below 2.5degrees, Check live data)

9 = not used

10 = Low Voltage (Battery voltage below 9.5 Volt)

11= Engine temp to high (Engine over 118 degrees, check temp sensor fault)

12 = Engine ECU request off (check engine faults)

13 = High Voltage (Battery Voltage above 16V)

14 Evaporator temp to low (Check evaporator temp in live data)

15 = Coding incorrect (Check AC and Engine coding)

16 = Compressor activation issues (Wiring issue to the AC compressor)

17 = Pressure sensor fault (Check AC pressure sender)

18 = Speed switch off (Engine rpm>3000rpm and vehicle speed<10mph)

Lucky for me, code 17– pressure sensor fault was present. I quickly scanned the vehicle for any DTC’s that may relate to the above code.

Now were cooking!

02071 Local data bus and 00256 Refrigerant pressure/temperature sensor – no signal/communication were stored in the central electronics module.

Ok, this is easy. Ill just check the pressure sensor for a high reference (most likely 5v), a ground and the signal (it should be somewhere around 1.5 volts with static pressure).

Wow…… I’ve never been more wrong!

A wise old mechanic once told me to “never assume” ……..because well……you look like a fool when you are wrong. This is the point I broke out a circuit diagram.

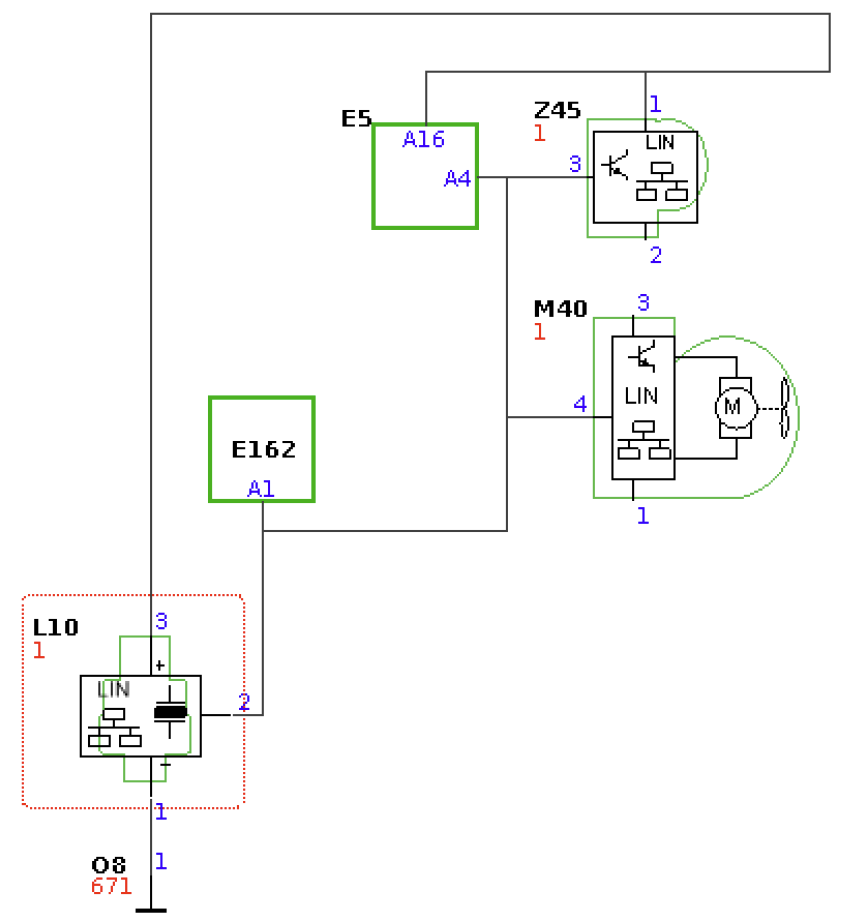

The AC pressure sensor used in this vehicle is a LIN (Local Interconnect Network) connected device. Once the penny dropped, it was a simple case of checking the output signal from the sensor with the oscilloscope.

This seemed OK until I gave the harness the old “wriggle and flex” test while watching the scope waveform. The signal would pull to ground while moving the harness at the inner guard / a pillar.

A close inspection of the harness at the body grommet showed the LIN cable insulation broken down and touching another “Bare” wire. This was the cause of the “Data BUS” and refrigerant pressure sensor DTC’s.

Once the short to ground was repaired, and the codes cleared, another performance test on the AC system was carried out.

Winner. The compressor now cycled and both low and high side pressures are behaving as designed and the centre vent temperature dropped to a cool 5 degrees Celsius.

What have I learnt from this experience? Well one day, I’m going to be the crusty old mechanic saying things like “Measure twice……cut once……….., Don’t count your chickens…….and, Watch out for those LIN BUS refrigerant pressure sensors……. they’ll get you every time”