ATE Brakes have a high tech solution to what may be seen as excessive brake pad wear. ATE Ceramic is designed to be a more efficient brake pad by being lighter in weight, producing less dust, and wear less in the same time and usage situations as “traditional” brake pads.

Part of the development process included “blind testing”, where professional drivers were given cars with a mix of ATE brakes and competitor brakes. What was noticeable, and one that’s sure to please the fastidious, is that the hard testing showed that the amount of brake dust produced was significantly less and therefore wheels remained cleaner for longer. This testing also showed that the actual wear rate, in comparison, appeared to be less than the competitors. However, these tests were done in controlled conditions so real world driving may not reflect these results. Both of these benefits were founded whilst still retaining the same level of performance as the competitor’s brakes.

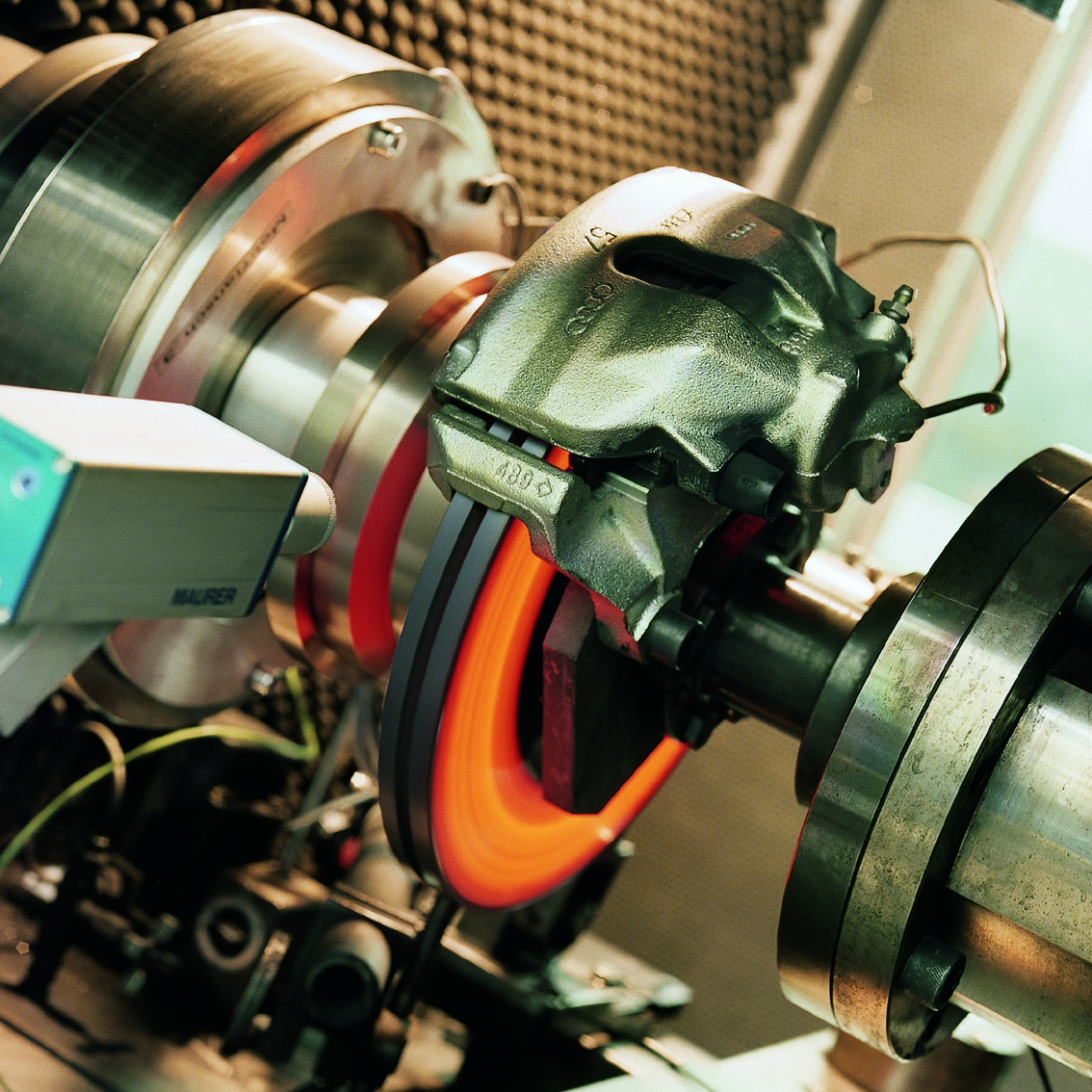

The formulation of the ATE Ceramic pads is what also helps in regards to reducing the wear rate. Normal pads will grip directly onto the brake disc itself, producing friction and slowing the car. This wears both pad and disc. ATE recommend that new discs be fitted if changing to the Ceramic pads in order to ensure a clean starting point.

Then the pads themselves effectively put a coating onto the discs, which is what the ATE Ceramic pads will grip to. This reduces pad and disc wear. ATE also recommend flat brake discs, not the perforated style, in order to again ensure optimal performance.

An added potential benefit of ATE Ceramic pads is the possibility of reduced brake pad noise. This is not always avoidable, however the specific formulation of the Ceramic pads has shown that noise may be reduced. The good news is, regardless, that in virtually all cases brake noise does not affect braking performance.